Guide to 3D Printing Services: Learn More About It

Introduction to 3D Printing Services

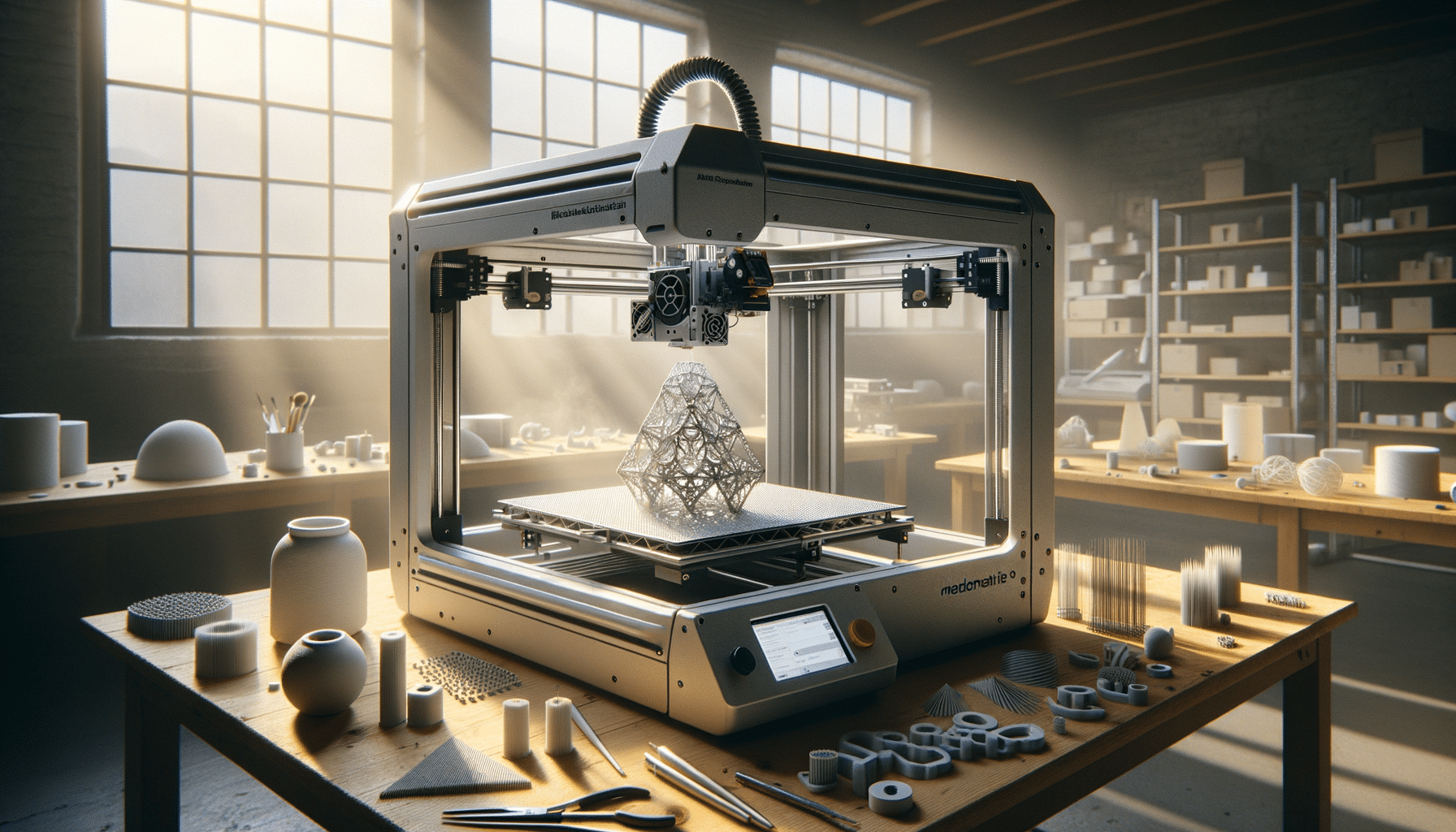

In recent years, 3D printing has emerged as a transformative technology with the potential to revolutionize industries ranging from healthcare to aerospace. This article provides an in-depth look at 3D printing services, exploring their importance, applications, and the technology that powers them. As businesses and individuals increasingly seek innovative solutions, 3D printing services offer a flexible and efficient way to turn digital designs into tangible objects.

The Technology Behind 3D Printing

3D printing, also known as additive manufacturing, involves creating three-dimensional objects from digital files. The process typically involves layering materials such as plastics, metals, or ceramics to build the desired shape. This technology is powered by advanced software that translates digital blueprints into physical forms, a process that can be customized to suit various specifications.

Several types of 3D printing technologies exist, each with its own strengths:

- Fused Deposition Modeling (FDM): This is one of the most common methods, where thermoplastic material is heated and extruded layer by layer.

- Stereolithography (SLA): Utilizes a laser to cure liquid resin into hardened plastic in a layer-by-layer process.

- Selective Laser Sintering (SLS): Involves the use of a laser to fuse powdered material into solid structures.

These technologies offer distinct benefits, such as the ability to create complex geometries that would be impossible with traditional manufacturing methods. The flexibility and precision of 3D printing make it a powerful tool for rapid prototyping and production.

Applications of 3D Printing Services

The versatility of 3D printing services opens up a wide array of applications across various fields. In healthcare, for instance, 3D printing is used to create customized prosthetics and implants tailored to individual patients. This personalization enhances patient outcomes and improves comfort.

In the automotive and aerospace industries, 3D printing is used for prototyping and producing lightweight components that contribute to fuel efficiency. The ability to quickly produce and test parts accelerates innovation and reduces time-to-market.

Additionally, 3D printing services are becoming increasingly popular in the fashion industry, where designers experiment with intricate patterns and structures that are not feasible with traditional textiles. This capability is pushing the boundaries of creativity and design.

Benefits of Using 3D Printing Services

3D printing services offer numerous advantages that make them appealing to businesses and individuals alike. One significant benefit is the reduction in material waste. Unlike subtractive manufacturing, which involves cutting away material, 3D printing adds material only where needed, leading to more efficient use of resources.

Another benefit is the speed of production. 3D printing can significantly shorten the prototyping phase, allowing for quicker iterations and faster decision-making. This efficiency is particularly valuable in industries where time-to-market is a critical factor.

Moreover, 3D printing services enable on-demand production, which reduces the need for large inventories and storage facilities. This capability aligns well with the growing trend towards lean manufacturing and just-in-time production.

Challenges and Future Prospects

Despite its many advantages, 3D printing services face several challenges. One of the main hurdles is the limitation in material choices compared to traditional manufacturing methods. While new materials are constantly being developed, the range is still narrower than conventional options.

Another challenge is the cost of 3D printers and materials, which can be prohibitive for small businesses or individual users. However, as technology advances and economies of scale are realized, these costs are expected to decrease.

Looking ahead, the future of 3D printing services is promising. Continued advancements in technology and materials will likely expand the range of applications and improve accessibility. As industries increasingly adopt additive manufacturing, the potential for innovation and efficiency will grow, making 3D printing an integral part of modern manufacturing processes.

Conclusion: The Growing Impact of 3D Printing Services

3D printing services are reshaping the landscape of manufacturing and design. With their ability to produce complex, customized objects efficiently, they offer a compelling alternative to traditional manufacturing methods. As technology continues to evolve, the impact of 3D printing services will only grow, providing exciting possibilities for innovation across various sectors.

For businesses looking to stay competitive, investing in 3D printing services can offer a strategic advantage by enhancing product development and reducing time-to-market. As the technology becomes more accessible, its potential to drive change and create new opportunities will undoubtedly continue to expand.